Waste treatment Compost plants

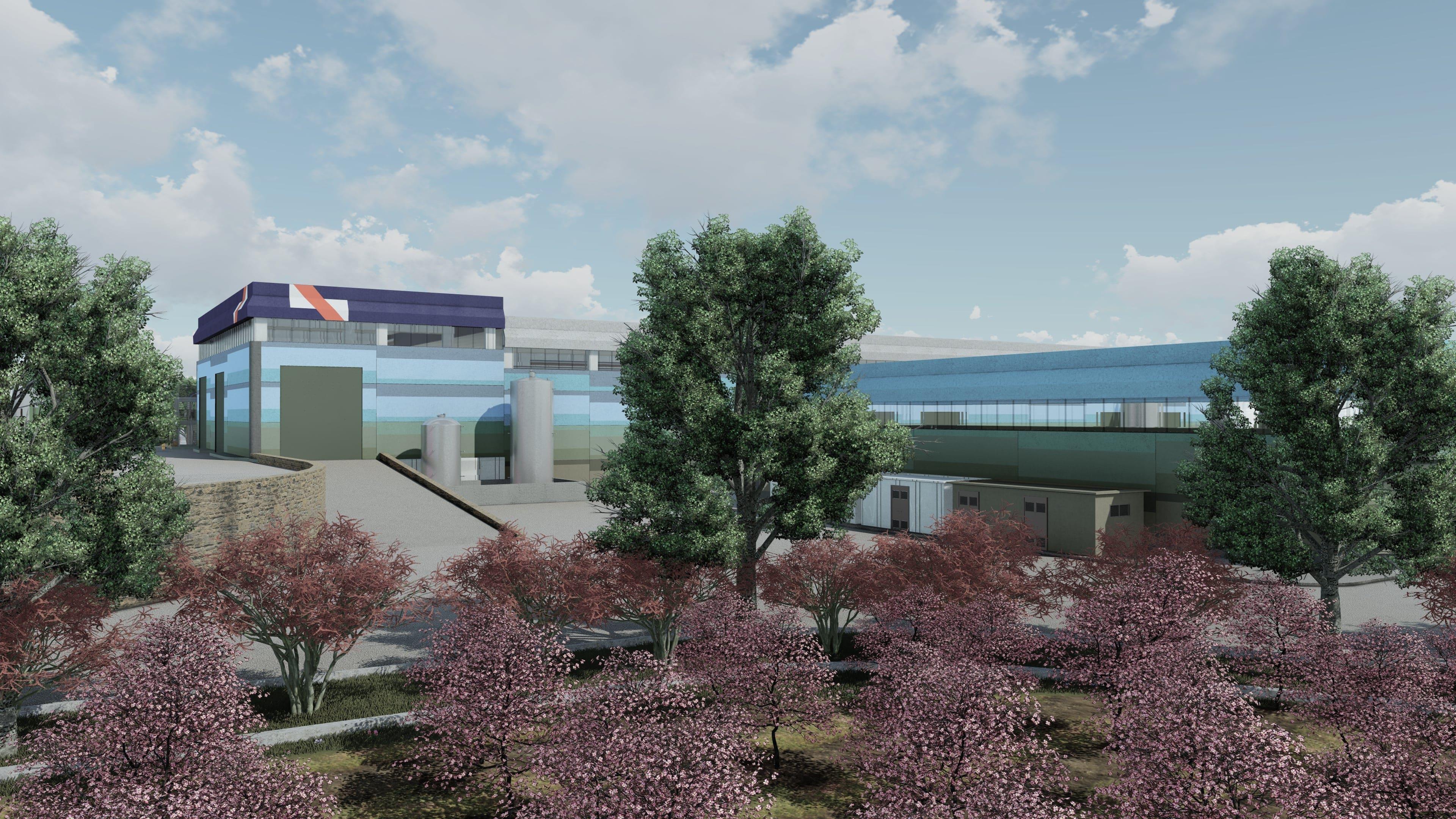

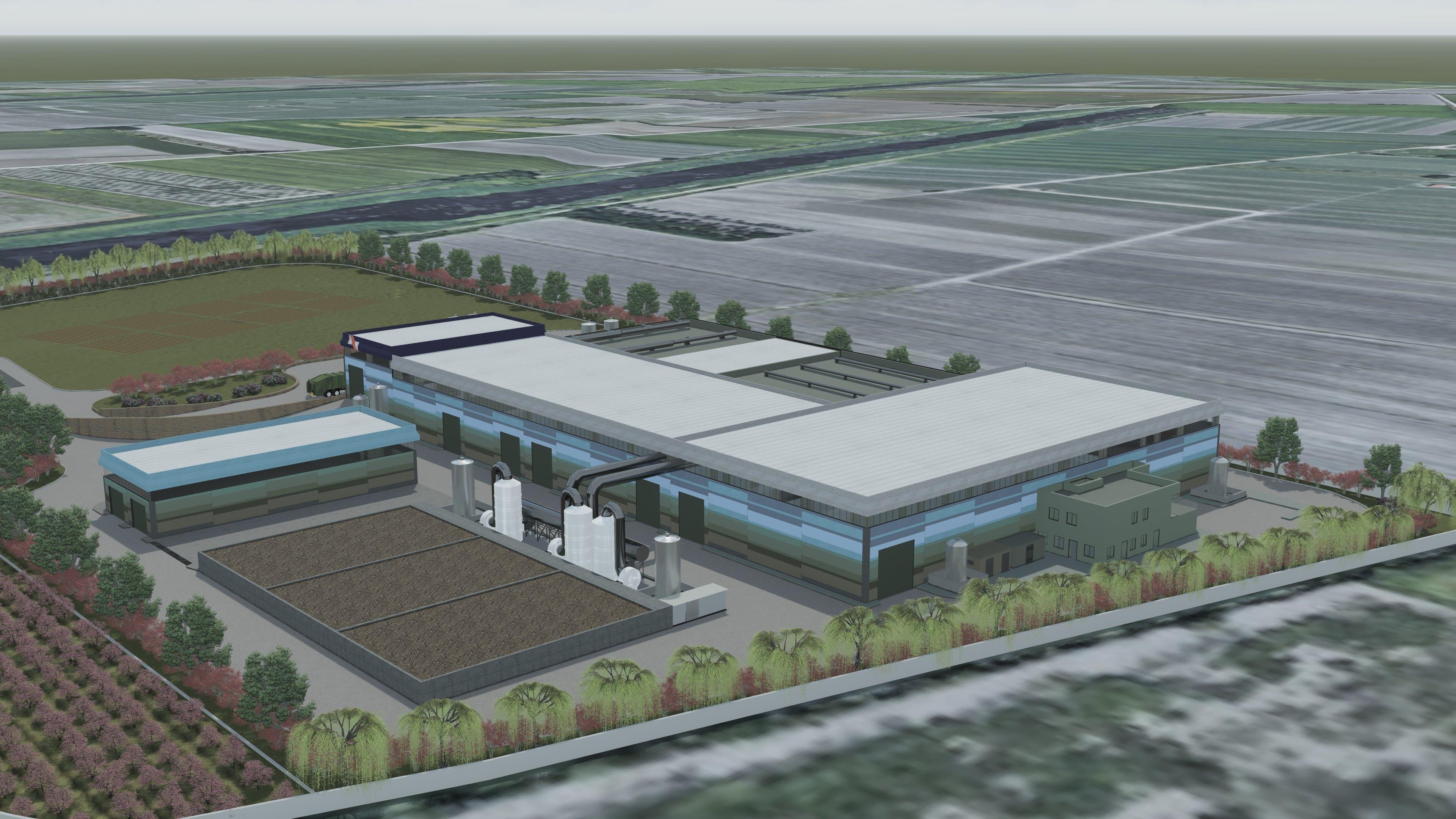

Detailed design of a compost production facility from biodegradable waste in Casal di Principe (Caserta - Italy)

The Campania Region has decided to improve the treatment of biodegradable waste generated inside the region through the construction of treatment plants and producing high quality compost. The goal is to satisfy the whole demand of the Region and to close the waste treatment cycle. This will guarantee its self-sufficiency, complying with the highest environmental standard and economic sustainability of the system.

The Company has been awarded with a project for developing the waste-recycling capacity in Campania Region. The Company is required to provide a range of services including preliminary design, detail design, studies and surveys for the realization of new treatment plants or the restoration/renovation of existing plants.

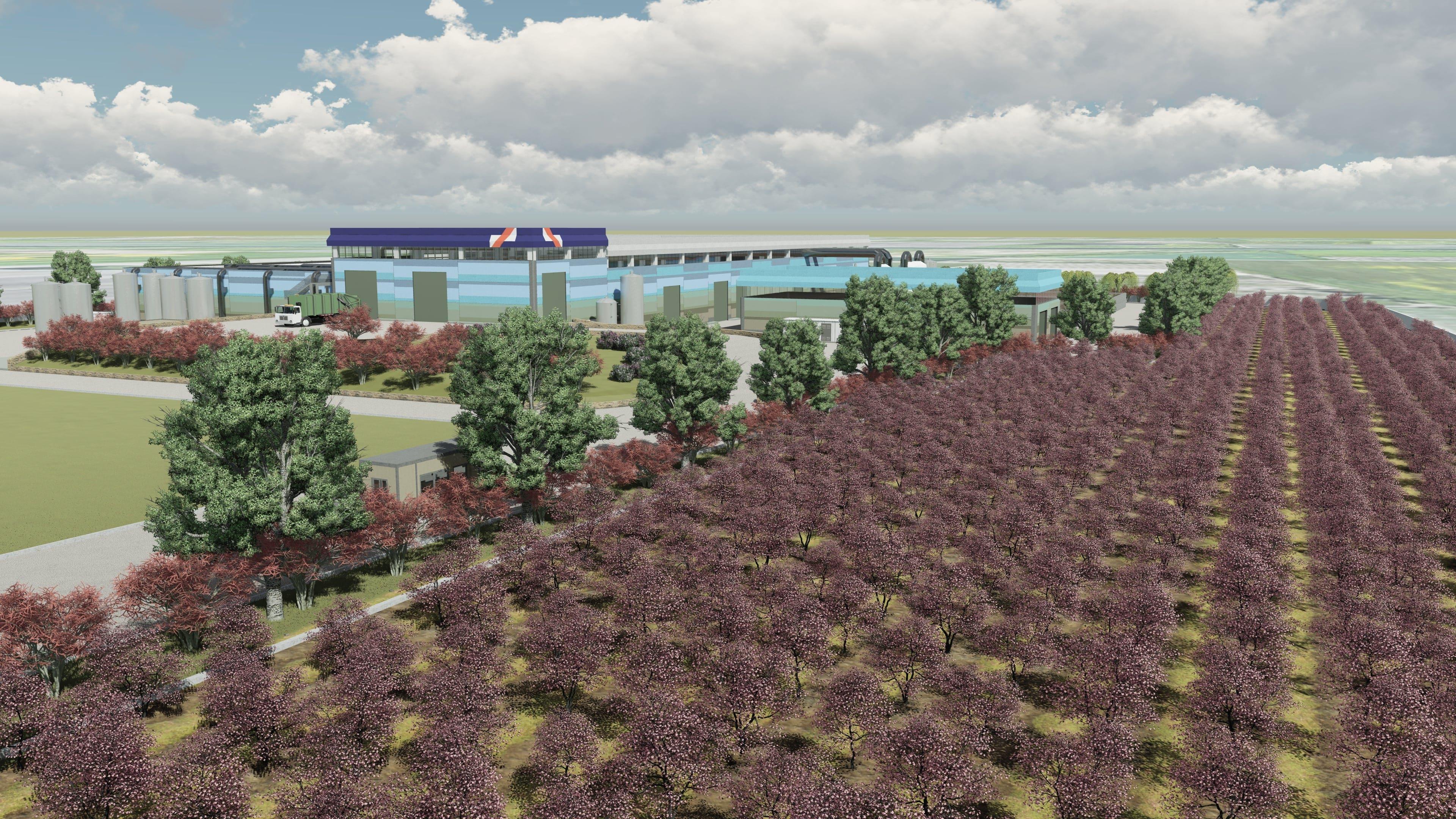

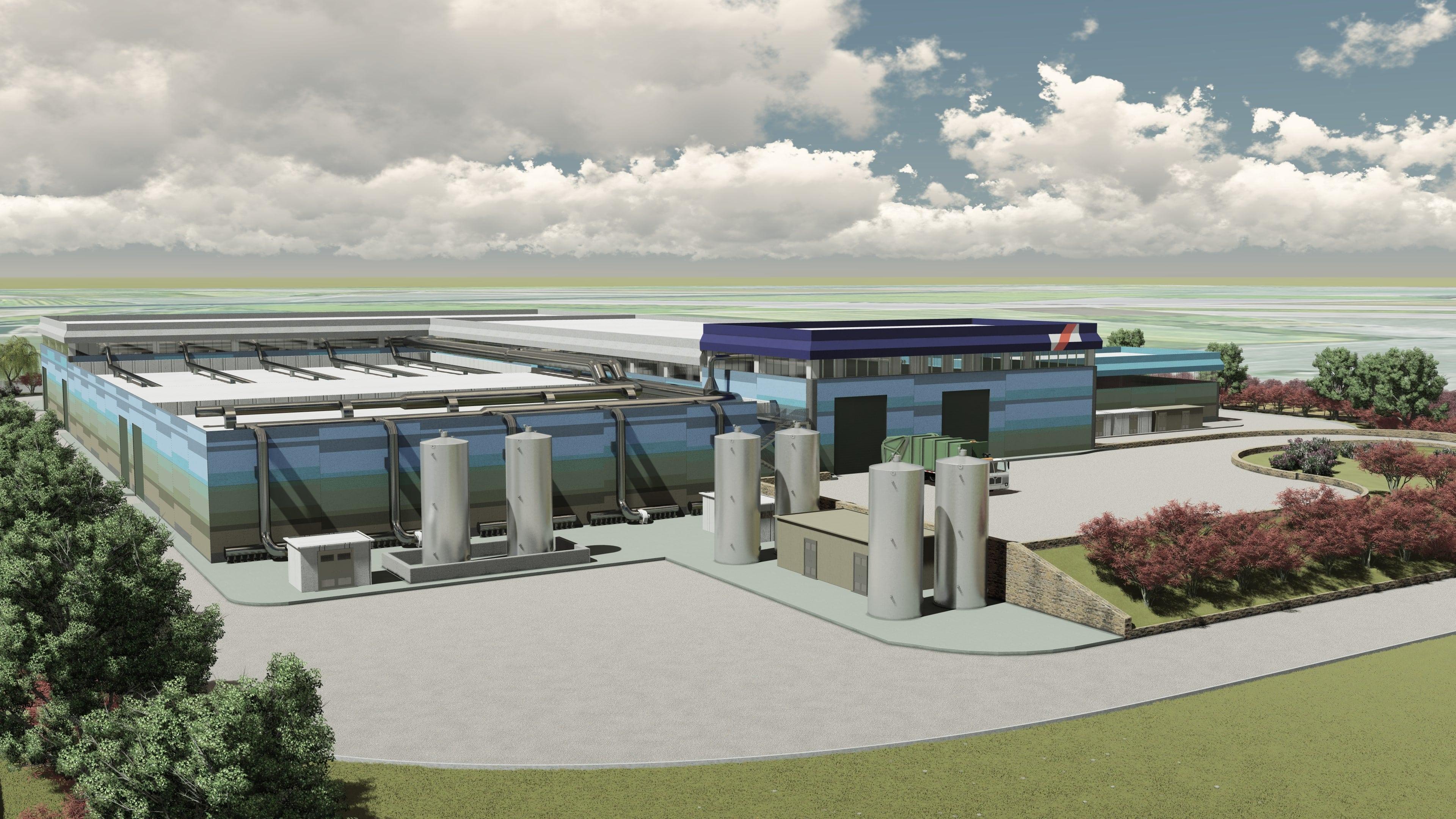

Within this Framework Agreement, the Company has undertaken the detailed design of a new 30.000 tons plant for the production of compost from biodegradable waste originated from waste sorting in the Casal di Principe municipality.

The plant capacity will include:

- 24.000 tons/year of biodegradable waste

- 6.000 tons/year of lignocellulosic (green) biomass, needed for the degradation of the waste.

A preliminary environmental authorization has been obtained.

The main objective is the recycling of biodegradable waste with the production of high-quality compost, thus requiring the certification from national Consortium of Compost Producers. The process is made of some operations, including mechanical selection, which produce the following fractions:

- High-quality compost;

- not recyclable scrap, to be disposed of in a disposal facility;

- plastic and metal fractions, to be forwarded to appropriate recycling facilities.

The plant is provided with a rainwater first flush system.

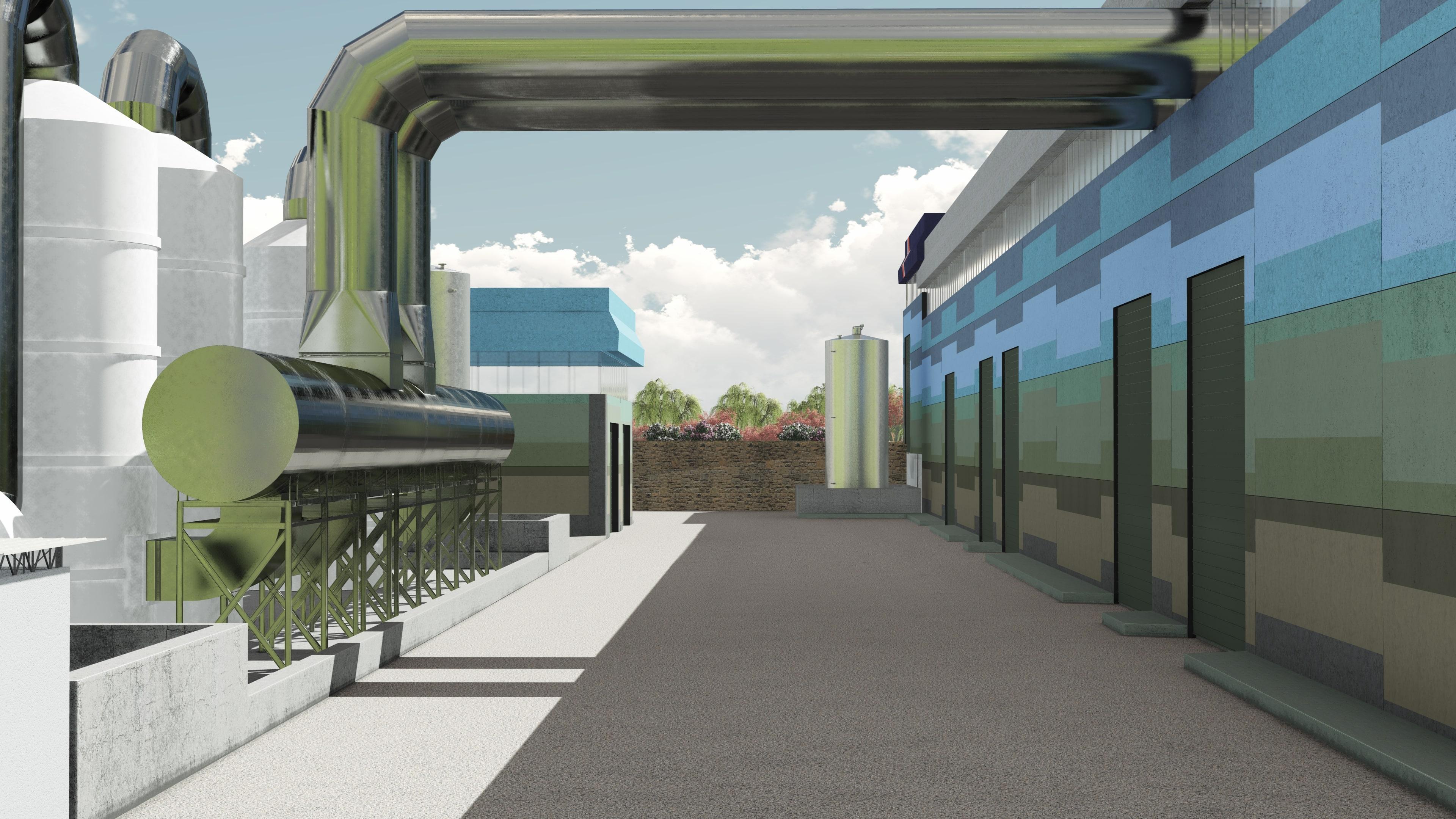

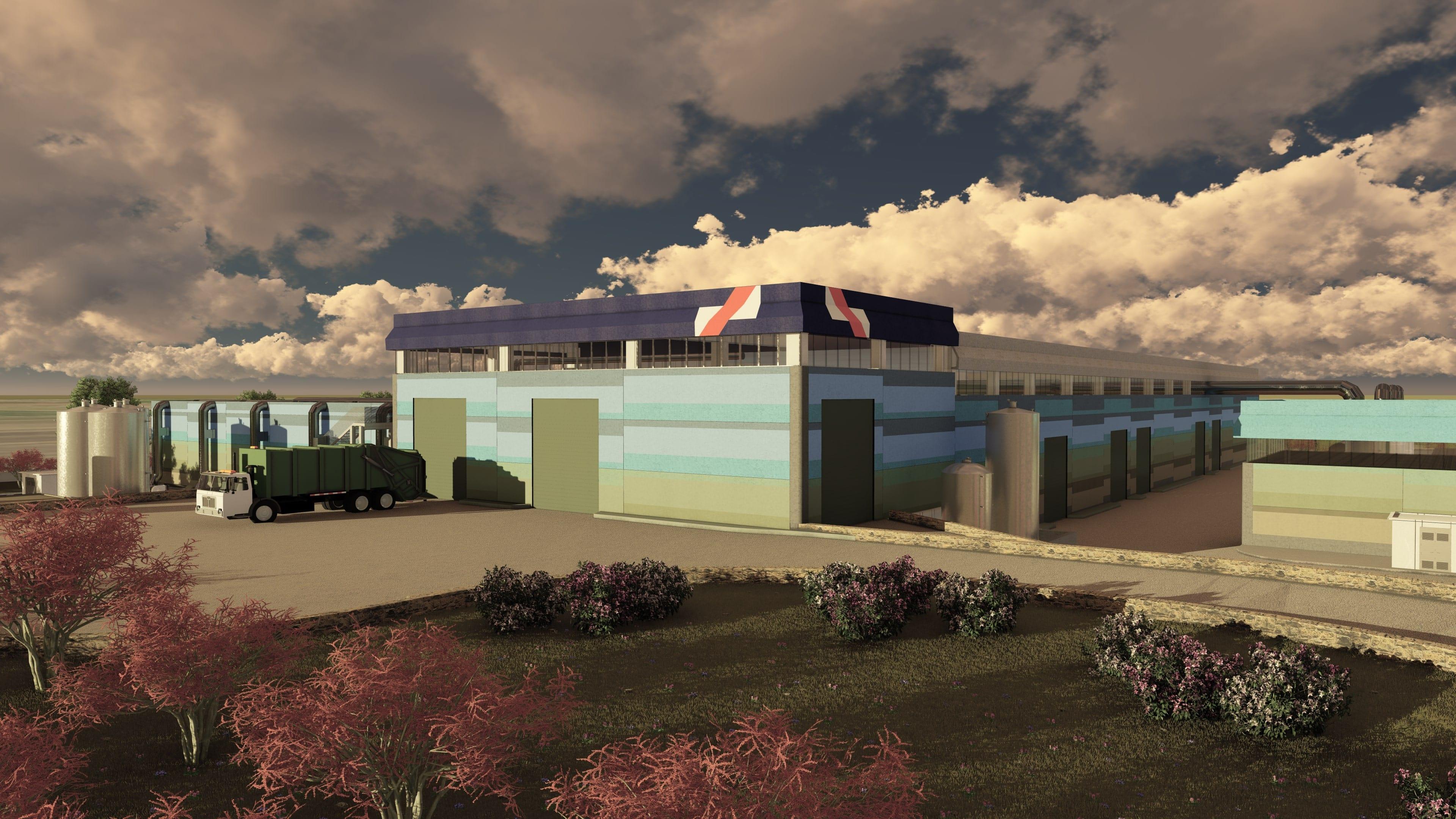

The waste will be delivered to the plant with appropriate vehicles, which will be weighted at the plant entrance for the registration; then, the vehicles will reach the destination where the waste will be unloaded in specific storage areas. All the areas where the waste is stored are provided with air-aspiration system, which transports all the exhausted air to a chemical and biological treatment system, composed of 3 scrubbers and a biofilter.

The plant layout allows the waste transport vehicles only in a specific area, where the waste is unloaded and operating machines take care of the movement inside the plant, thus reducing the accidental dispersion of waste out of the storage areas.

The wheels of all the vehicles will be automatically washed before exiting the waste storage building.

The green biomass is transported in the same building, on different storage areas, through a specific access, functionally separated. The biomass will be transported with a mechanical shovel to a shredder machine, which will deliver the shredded biomass to an area where it will be mixed with biodegradable waste.

The mixture will be nourished to the biological treatment area, which is divided into three sections:

- accelerated biooxidation in bioreactors;

- primary maturation in aerated piles;

- secondary maturation in piles which are frequently turned inside out.

Bioreactors will be realized in concrete, with airtight doors in order to keep the oxidation parameters under control. The air will be forced through the waste from underneath the pit and the whole phase will last 18 days.

After the biooxidation phase, the mixture will be transported, with a mechanical shovel, to the primary maturation area, which is strategically designed facing the bioreactors, reducing to the minimum the transportation of waste inside the plant.

In this area, the mixture is placed in piles on a pavement similar to the one in the bioreactor, with air force to flow from the bottom through the whole piles, thus reducing potential anoxic areas.

This phase will last 42 days; after, the mixture is transported to a sorting machine, which will select and separate bigger fractions to be disposed of. The resulting material will be moved to the secondary maturation area, where will be stored for the time necessary to complete the 90 days process.

In the secondary maturation area, the material is stored and mixed up with a windrow turner which will guarantee a perfect aeration of the piles in order to complete the aerobic degradation of the material.

Once completed, the mixture will be nourished to a fine scrap sorting machine/windsifter, which will produce:

- stabilized compost to be stored and destined to the market;

- other organic material which will be separated from plastic scraps and will be used again in the process.

Client

Campania Region

Location

Casal di Principe (Caserta) - Italy

Services

Detailed Design

Cost of works

Euro 13,483,318,10